Cellar Management

The quality of our dispensed drink products are only as good as the care we take in how we maintain and clean the equipment needed to provide them. The following steps are to guide you how best to manage the environment and equipment that you will be using to provide drinks to our customers.

Glossary

Coupler

The handle that attaches to a keg.

Pressure Gauge

Shows how full gas bottle is.

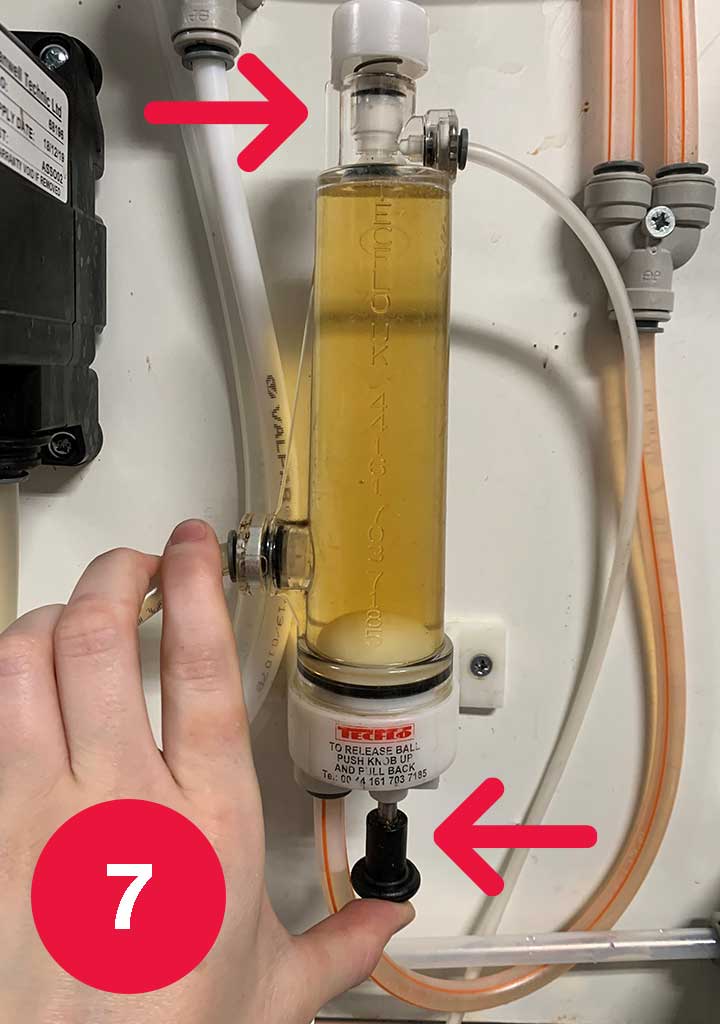

Cellar Buoy

Should be filled with beer/cider with the circle “float” at the top.

Gas Switch

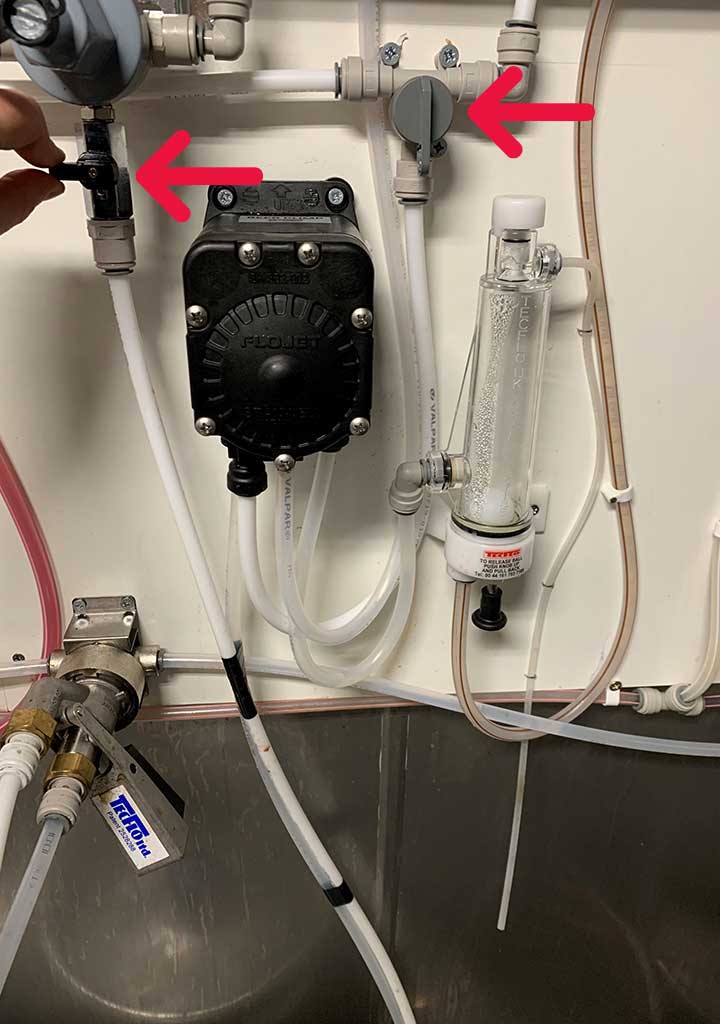

As seen here being turned to the off position. This switch is connected to the keg as seen by following the pipe from it, the grey switch on the right is the gas switch for the actual gas pump, should be no need to ever turn this off.

General Management

- Structure of the cellar should be clean and in good order, repair and condition to enable effective cleaning.

- Cellar temperature should be constantly maintained at 11-13oC.

- Suitable and sufficient ventilation should be provided (to reduce humidity and condensation).

- Access to the cellar should be free from obstruction.

Hygiene Standards

- Cellars should be kept clean at all times and kept tidy – free from anything that does not belong here at all times (a weekly cleaning schedule must be followed).

- Cellars should only be used for the storage of specified beverages (beers, ciders, spirits, soft drinks or wines) and dispense equipment, they must not be used for storage/preparation of perishable food.

- Cellar tools should be in good working order and stored in hygienic conditions.

- Drains and scuppers should be kept clean and fresh.

Changing a Keg

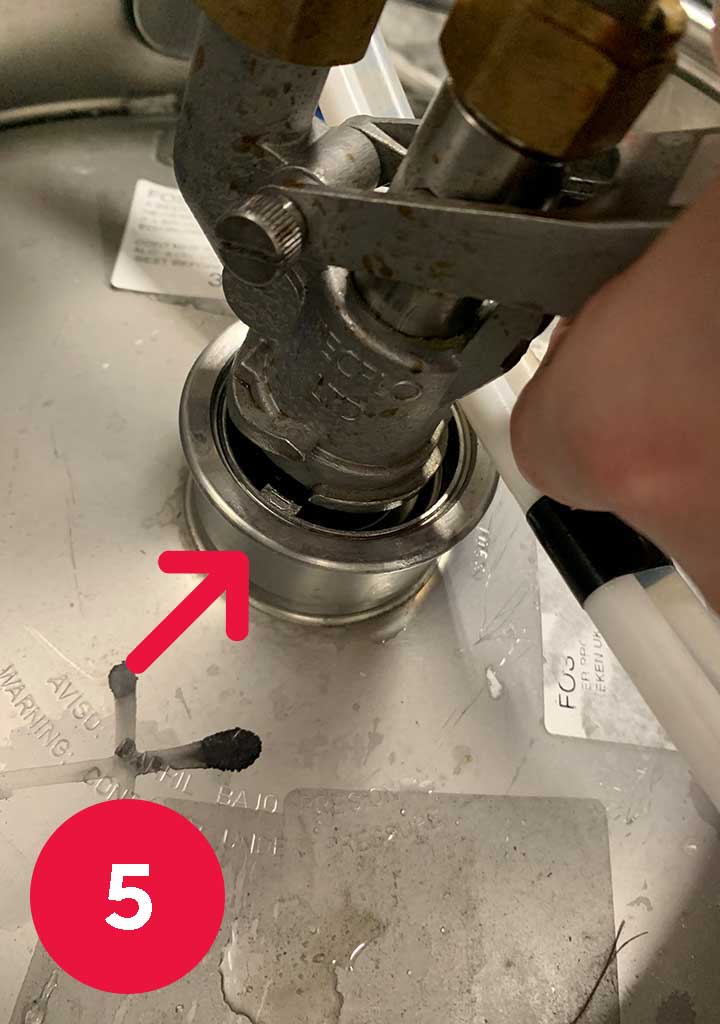

- You enter the keg room to see the cellar-bouy is empty, and the ball at the bottom. First check the keg is actually empty (if not empty check gas).

- Turn off the gas, normally a plastic switch just above. If you’re not sure what one, just follow the coloured pipe from the coupler(handle).

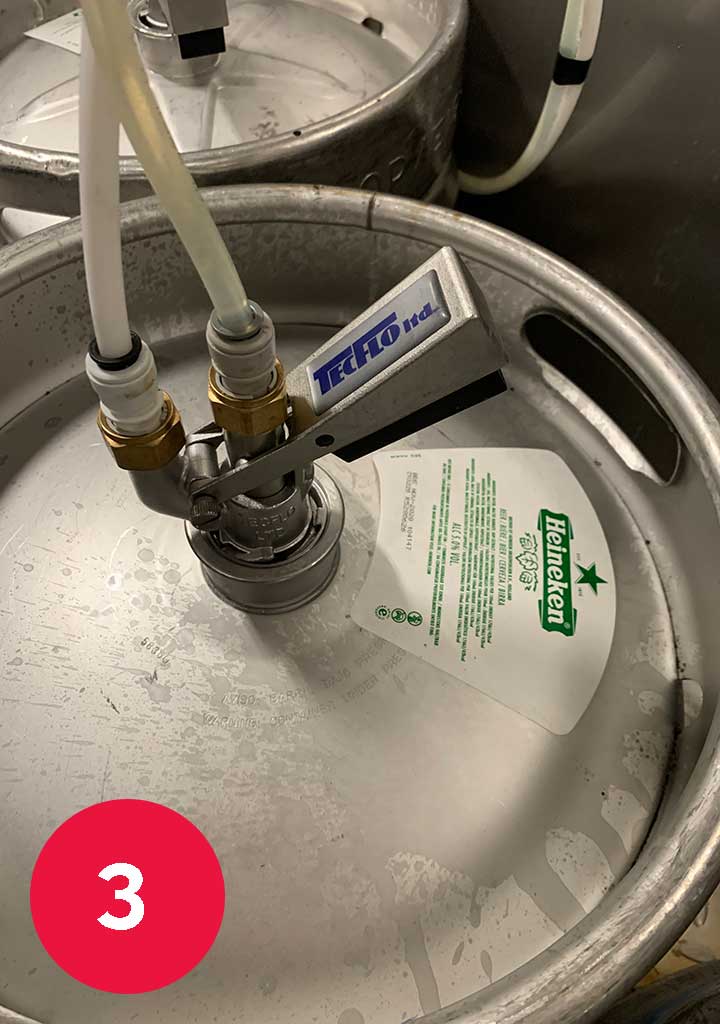

- Stand back from the keg as it is pressurised, click and lift the coupler and turn anti-clockwise to take off the keg.

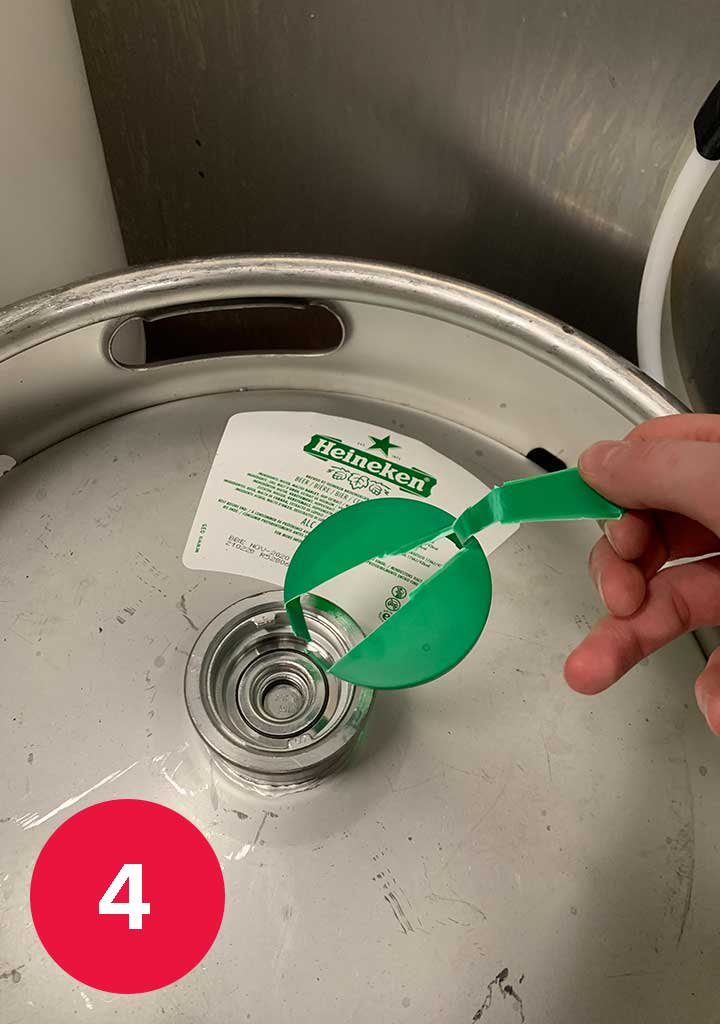

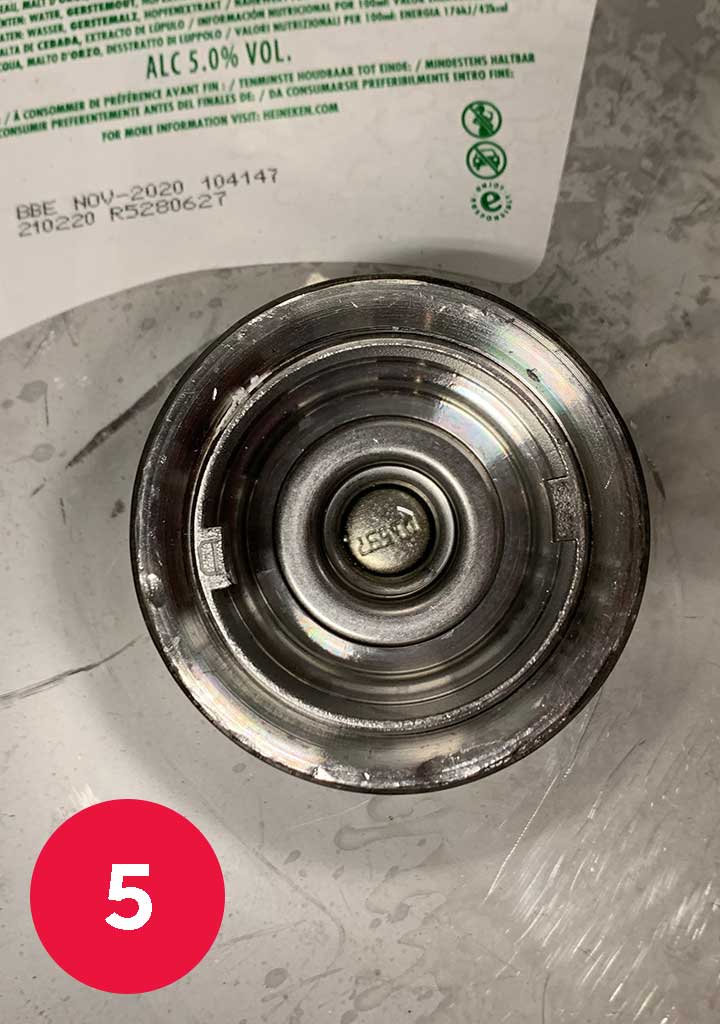

- Choose a new keg (ensuring date rotation) and rip off plastic top.

- Ensure the coupler is raised to it’s highest position and locate the tapered guides on the keg and insert. Turn fully clockwise and firmly depress until clicked into place.

- Turn the gas back on.

- Push the top of the cellar bouy (the white bit) firmly to fill the bouy with beer/cider, then firmly push the bottom to release the float (ball) back to the top.

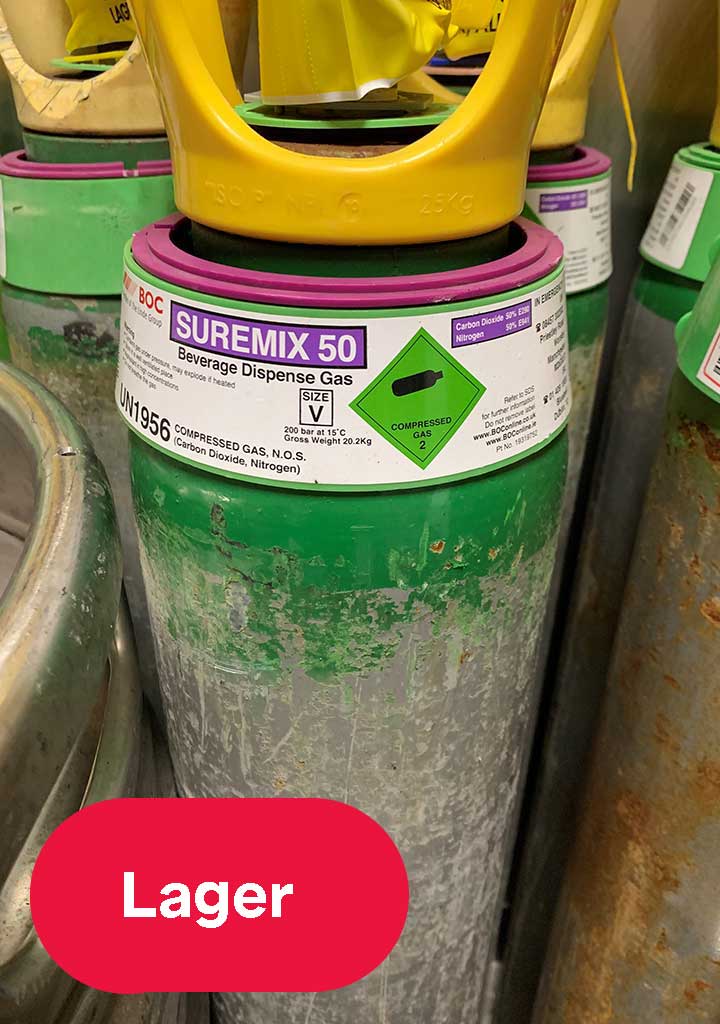

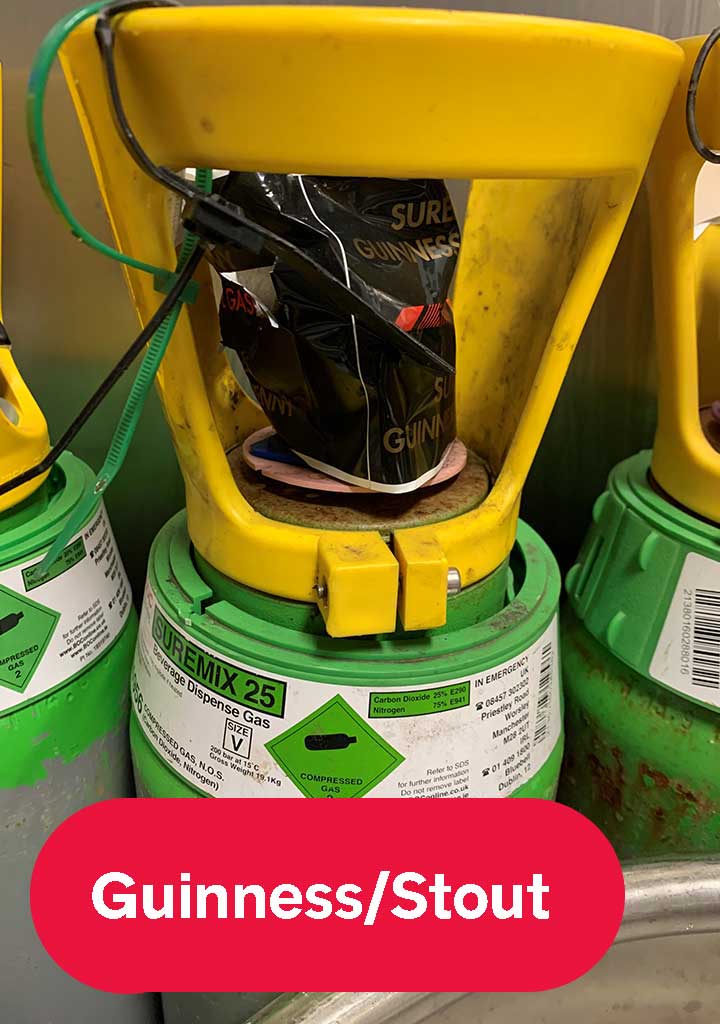

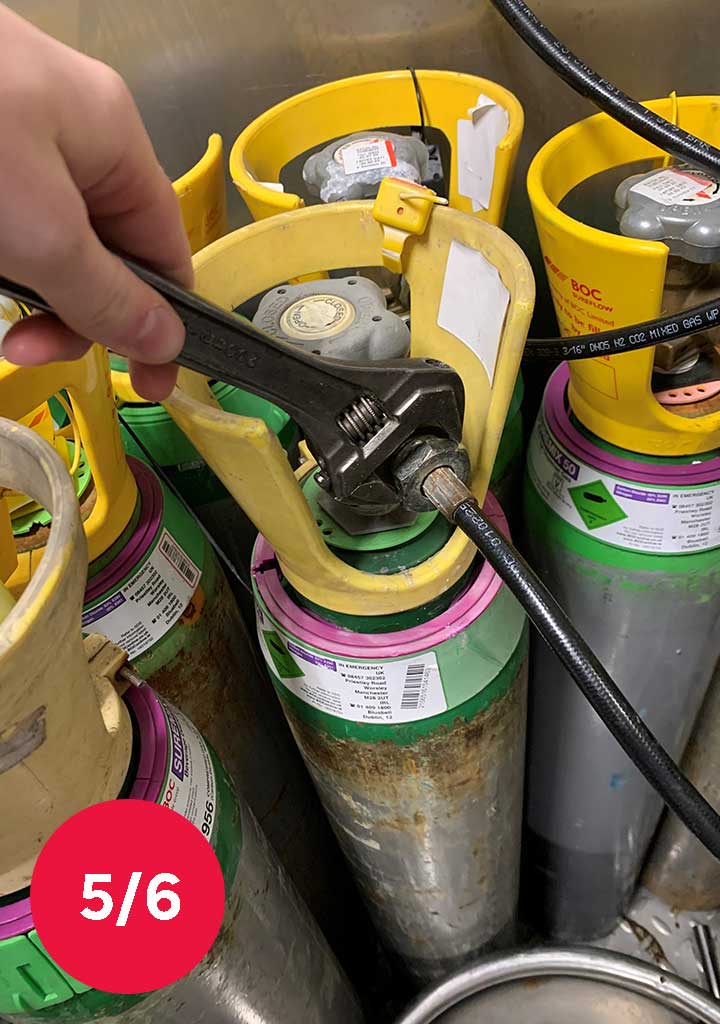

Changing the Gas

This is applicable to both Guinness and Lager Gas. Ensure you use the correct gas. Lager is “SUREMIX 50” Guinness is “SUREMIX 25”

- The pressure gauge will read empty. Turn the gas canister top fully clockwise to close. If your gauge has a pressure release, pull this now.

- Using your spanner unscrew nut on the pipe connected to the bottle until it is removed.

- Place the empty safely and securely to the side, do not leave it where it can fall and roll about.

- Position and secure new bottle in place.

- Take the plastic wrapper off, and insert the pipe connection, screw until finger tight.

- Using your spanner, fully tighten the nut, if not secure or threaded correctly, gas will leak (you will know quickly as it’s very loud when escaping).

- Unscrew the top anti-clockwise to the open position. Instantly your pressure gauge should read full once again. You will hear a small hiss, don’t worry.

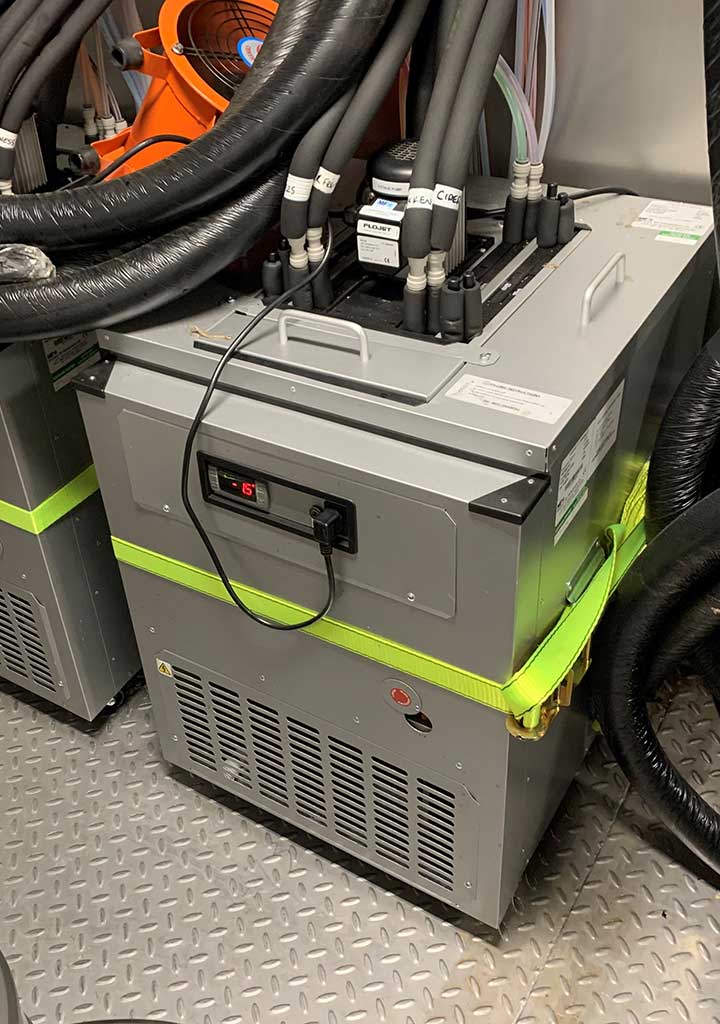

Beer Coolers

- The vents at coolers should be kept clear to ensure good circulation of air.

- Try not to let inside ice up, if they do, turn off for as long as possible during bar close, and turn on again in good time before opening.

- The inside pumps can get dirty and affect the effectiveness. If this happens the maintenance company (asstech) can come and clean these, or replace them.

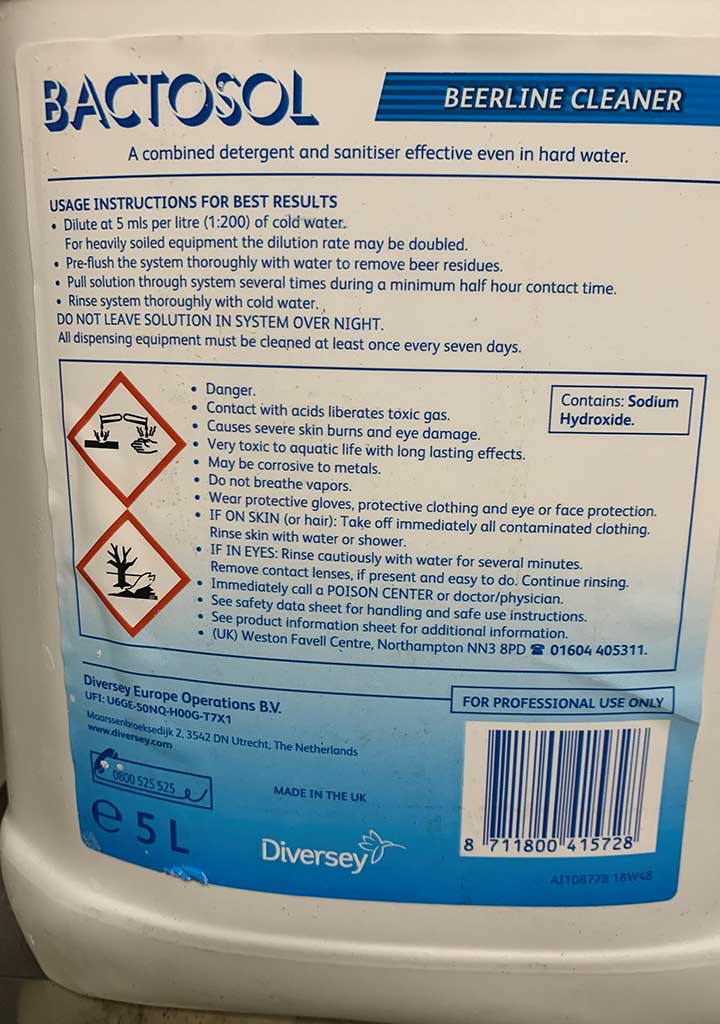

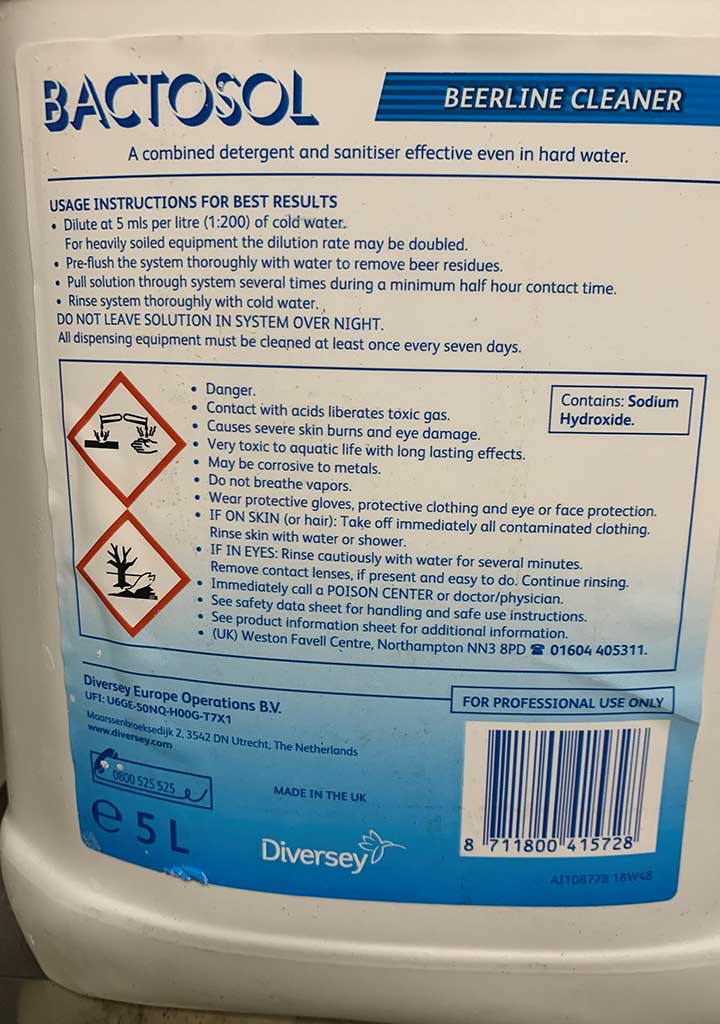

Beer Line Cleaning

- First ensure you have correct PPE, gloves, goggles and apron.

- Turn the gas off to each keg but leave the gas on to the pump, and attach the couplers to the cleaning sockets on the wall.

- Fill cleaning container with clean water and dilute beer line cleaner according to instructions on the bottle.

- Switch the gas on to cleaning mode, normally at the start of the cleaning line.

- Bleed the fonts as if you were filling with lager to fill these with cleaning solution.

- Pull the cleaning solution through your taps, placing a bucket underneath them. You will know the fluid is through as it will become clear, and the water feels "silky".

- Leave to sit for a minimum of 1⁄2 an hour (check fluid instructions in case they differ).

- Empty container of the cleaning solution, rinse, and fill with cold clean water.

- Bleed fonts again to fill with clean water.

- Pull through the clean water to rinse the pipes. Once through the water will lose it’s silky feel. Pull through at least 10L to ensure its flushed.

- Reattach the couplers to the correct kegs and turn the gas back on to all kegs.

- Bleed fonts again to fill with the keg contents, then pull through the taps into your bucket again, until beer/cider is pulling through clearly.

Beer Line Cleaning

If unsure please ask for help, this can be a hazardous task when carried out due to working with strong chemicals.

Stena Lines standard beer line cleaner

Example of cleaning bucket, can be many forms, most very similar in design

Beer lines hooked up to cleaning line on wall, filled with line cleaner

Pulling cleaner through beer pump

Once the cleaning fluid has run through the pumps clean water is to be run through to rinse the pumps thoroughly. Solution shouldn’t be left in the pumps over night.

Troubleshooting

- Float dropped but beer in keg: check the gas.

- Float not filling up: Is the coupler depressed fully.

- Beer pouring very slowly: Check gas.

- Beer extremely lively: Cooler either too hot or too cold.

- Beer very flat: Cooler too cold, or keg date may be out, or the keg has been sat open too long due to slow sales. Also can be due to warm/old glasses.

- Beer pouring very oddly can also be due to the wrong nozzle on the tap, Guinness nozzles have lots of very small holes in them where as lager/cider nozzles are just straight through.

- The switch at the bottom to release the floats can often require a lot of force to push up and release.

Guinness Nozzle

Lager Nozzle